Special projects

DOCTOR WINDER

Category: Paper industries

The doctor winder installed by IAS in the first half of 2016 ensures efficient and accurate cutting. The installation was based on partially completed software that was made available by the client. Next to the control concept, which required that the controllers be modified, and safety features be integrated into the software, special attention was paid to the process optimisation and sequence control including the ease of use. The integration of locks for operational safety provided an additional challenge.

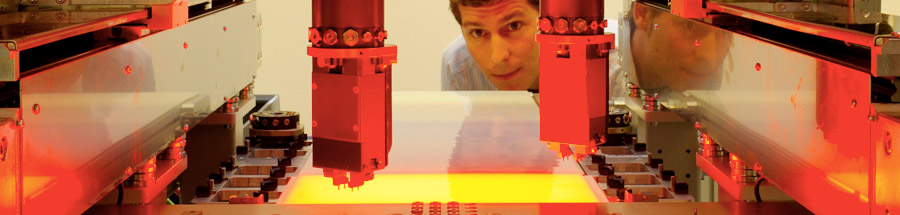

STAMPING STATION

Category: automotive industries

A recently completed stamping station is also finding its use in the paper industry. Central issues here included the adaptation of a control concept, consulting support for the development of a hydraulic concept, and the realisation of functions for pressure and volume regulation (master - slave). The project also included the adaptation of a regulation concept as well as the realisation of process optimisation and sequence control including the ease of use. The integration of locks for operational safety was also required here.