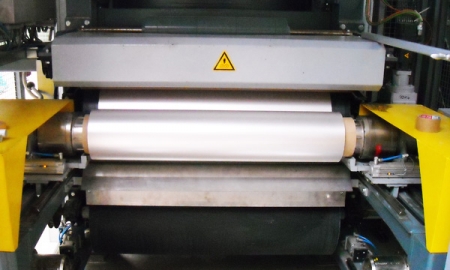

Mica paper machine

Mica paper machine

Project description:

After the specifications were determined, the project was realized together with the client.

The coordination of the interfaces between the various vendors and the client was followed by the planning of the hardware with emphasis placed on safety relevant aspects.

Next, software was written and the control cabinets were constructed under the watchful eye of the assembly supervision.

After the initial start-up, it was time to optimize the plant operation and establish the connection to the client’s recipe control system.

Note: mica paper is used for insulation in high-voltage machinery.

IAS Project:

- Project management

- Coordination of plant vendors

- Interface coordination

- Specifying and ordering hardware components

- Hardware planning

- Planning of emergency stop system

- Control cabinet constructoin

- Visualisation MP370 / Cimplicity

- Creation of a process description for machine and material (Basis: Plant vendor description => combined with company know how => discussions)

- Drive control

- Initial start-up

- Process optimization