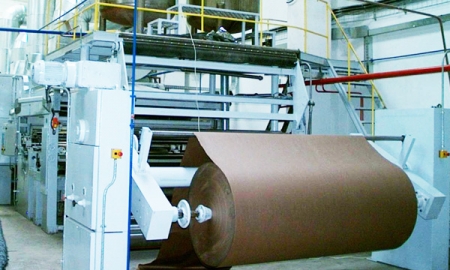

Impregnating machine

Horizontal Impregnating machine: Reengineering

IAS scope:

Automation of a resin impregnating machine (ca. 250 I/O).The function is realised in a PLC from Siemens (S7-300). The operator controls the machine via two touch-panels MP 270. One of the touch panels and a part of the drives and sensorik is located in hazardous area (EX). The web is driven from three frequency converters. The tension of the web will be measured and used as control variable for the proportion of different rpm. The exhaust dryer fans are controlled from three frequency converters. All frequency converters are connected by profibus with the CPU.

- Creation of the specification map together with the customer.

- Specification of the electrical components especially to avoid injury of the operators, to reach high availability and to fulfill the regulations of the hazardous area (EX).

- Hardware engineering.

- Construction of all electronic cabinets and local panels.

- Programming the function and execution of a FAT together with the customer in our office.

- Initial start-up in Bukarest: